Care your oil instead of just filtering it — for the maximum service life of oil, components and machine

CJC® Offline Filters: Your solution for absolutely clean and dry oils and fluids

Offline Filters

CJC® Offline Filters clean, dry and maintain the oil or fluid in your machines quickly and cost-effectively. Whether hydraulics, gearboxes or thermal oil systems, whether mineral or synthetic base oils and whether how heavily loaded, the offline filter from CJC® is precisely configurable to the specific conditions of your machine and the impurities in your oil or fluid. Installed in the offline circuit, it ensures maximum oil cleanliness regardless of the operation of the machine. The filter removes solid particles, water, oxidation residues and acids effortlessly and permanently.

How you benefit from installing a CJC® Offline Filters on your machine

Maximum oil and fluid cleanliness is the be-all and end-all for reliably functioning machines and resource-saving maintenance. It’s that easy — watch our videos:

The advantages briefly explained

The offline filter in detail

The advantages briefly explained

The offline filter in detail

The advantages briefly explained

The offline filter in detail

Product Advantages — CJC® Offline Filters

Customized solutions

Perfectly adaptable to any machine and any oil or fluid. The CJC® Offline Filter is individually configurable, thanks to its modular design. Optionally with customer-specific sensors for integration into your condition monitoring system.

Maximum oil cleanliness

Highest oil purity and maximum wear protection. The CJC® Offline Filter removes all contaminants – regardless of operation, continuously and highly efficiently. For maximum service life of oil and components.

Economical & ecological

Depth filter made of 100% natural fibers — 0% plastic and 0% metals. High recording capacities and thus long filter life ensure the excellent price-performance ratio of the CJC® Offline Filters.

Easy installation & maintenance

Easy to install as an offline filter in an independent circuit. This also means changing filters without machine downtime. Low-maintenance, robust and durable, the CJC® Offline Filters also convince.

Areas of application — CJC® Offline Filters

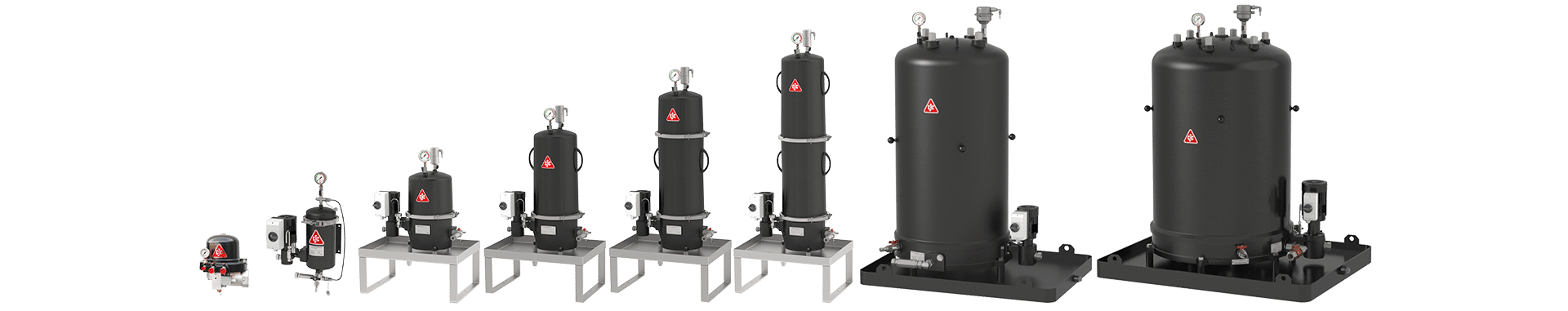

Modular design — CJC® Offline Filters

The integrated CJC® Depth Filter Inserts

Separation capacity:

- Solid particles (wear and impurities)

- Water – free, emulsified and dissolved

- Oil degradation products and oxidation residues (Varnish, oil sludge)

- Acids

Type of filtration:

- Depth filter with extremely high recording capacity

Inner surface:

- 120-150 m² per gram

- The largest depth filter insert has an internal surface of > 2,066 ha = > 2,894 football fields

- The smallest depth filter insert has an inner surface of > 5 ha = > 7 football fields

Thanks to the modular design, the number of depth filter cartridges and thus the absorption capacity can be adapted to the individual dirt input.

Volume:

- The largest depth filter insert has a volume of > 504 Litres

- The smallest depth filter insert has a volume of > 1.5 Litres

Filtration degree:

- 3 µm absolute, retention rate down to 1 µm (Micrometer)

Filter material:

- 100% natural fibres – meets the requirements of the Circular Economy Act

For oils and fluids that tend to acidify very quickly, an additional filter material may be used, which increases the neutralization capacity against acids many times over.

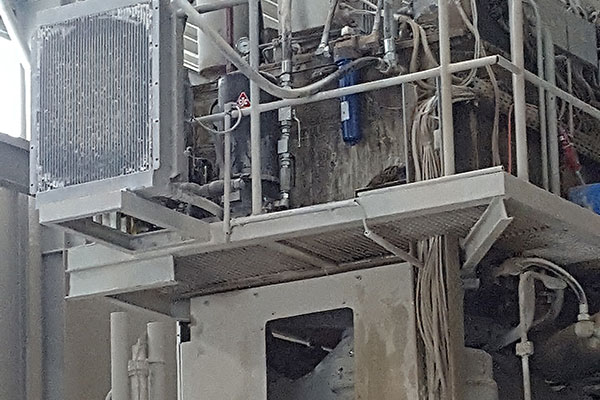

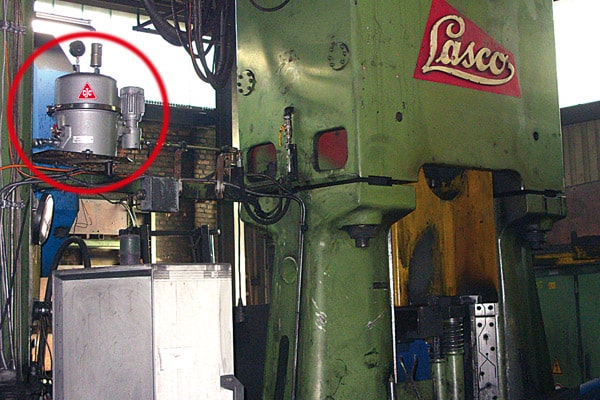

Customer cases

Find out in our application studies how operators benefit from installing a CJC® Offline Filter.

“I am completely satisfied with the investment. Oil drying takes place very quickly and without system downtime. In this way, we maintain production, have time to look for the fault, save ourselves the oil change and disposal and maintain the oil quality.”

“I am pleasantly surprised how quickly the oil was cleaned. The service life of the in-tank filter has been extended significantly, and the maintenance effort has been reduced obviously. The result is so convincing that we decided to purchase a CJC® offline filter for the forge as well.”

“It is remarkable how clean the oil has become. We have already tried several filters, but only with the filters from CJC®, we did achieve the desired oil purity. In the meantime, we have already retrofitted four systems in our production with CJC® offline filters.“

„We are convinced […]. The oil is clean and clear […] otherwise there would have been huge damage of several thousand euros with enormous downtimes and production losses. […] impressed […], that the fine filtration of the oil has such an extreme impact on wear pattern. […] remaining five crushers were also equipped with CJC® offline filters.“

„Since the CJC® filter was put into operation, the service life of the oil has multiplied. The oil remains as clear as fresh oil despite the heavy dirt load. We visibly have less abrasion on the components. The CJC® filter is a simple but very effective measure to reduce wear and thus maintenance efford.“

„We are very satisfied with the CJC® offline filter. The filter insert has to be replaced only once per year.”

„The high quality of the die-cast parts relies on well-functioning production plants, which can be achieved only with proactive maintenance and, among other things, an absolutely clean operating medium (HFC fluid).“

„We were so convinced by the results that we equipped another drop forging hammer with a CJC® offline filter CJC®.“

“The comprehensive oil analyses of OELCHECK convinced us. They clearly show the continuous improvement of the oil quality – further gearboxes will be retrofitted with CJC® filters.”

“Having undertaken an assessment of our onsite lubrication activities, we introduced a program of offline filter installations as a proactive maintenance strategy across the site. This has allowed us to move from a situation where oil replacements were frequent to nearly no oil changes at all. CJC oil filters have been a huge help in this program.”

“Within just two hours, the oil in the gearboxes could be cleaned to such an cleanliness level that it was comparable to fresh oil.”

„The perfect solution to help our oil-consumption-ratio concerns, now we can save on oil change and can increase our machine reliability.”

„With the use of the CJC® offline filters, the oil quality has improved to such an extent that the annual oil change is eliminated and valves are spared.”

„ “The CJC® offline filters were installed because it is only possible to work continuously with clean oil due to the fine filtration, which is essential for the proper operation of all valves and components. It is also noteworthy that the oil service life and the oil change intervals have been extended. So we also achieved economic savings: reducing the waste oil amount and thus protecting the environment.“

„The reason for installing the CJC® offline filter system was not only the avoidance of failures and improved maintenance of the machines but also all the high savings in oil costs and the associated reduction in the amount of waste oil – — an advantage for the environment. Due to the filtration with CJC®, we can use the oil in the hydraulic system for up to 4 years.”

„Since the start-up of all twelve plastic injection moulders machine-manufacturer-equipped with CJC® off-line filters, no breakdowns of hydraulic systems of any of the machines have been noted. At the same time, we have observed a prolonged lifetime of pumps and proportional valves.”

„Installing the CJC® offline filters is by far the best preventive maintenance measure we have ever undertaken […] We had no unforeseen failures due to resins or other contaminants in the valves. Cleaning the hydraulic tanks was also not necessary.”

„Before the installation of the CJC® Filters in all our injection moulders, we had to change the oil and the in-line filters very often, and still the system remained contaminated. We spent a lot of hours on maintenance of every engine because of the contamination, which we at that time did not think was so important. A short while after installation of the CJC® Filters, we noticed a reduction in the stoppages as the oil no longer was contaminated by particles, resins and water. It has been one of the best maintenance investments until today.“

„We are very satisfied with the results after installing CJC® Fine Filters on our hydraulic presses, and all new machines are immediately equipped with CJC® Fine Filters.“

„Thanks to the CJC® offline fine filters, the automatic lathe now works much more efficiently. The number of system failures and the associated costs have been reduced. Filtration with CJC® is invaluable, even though we only use 60 litres of oil.“

„Karberg und Hennemann has kept its promise regarding the performance of the CJC® filter system. Through the multiple uses of our hydraulic oil, we significantly reduced running costs and expenses as well as storage volumes and the associated environmental risks.“

“We were convinced of the result in a short time and can only recommend the CJC® offline filter 27/27 with the CJC® fine filter insert B to prevent wear at an early stage.”

“I no longer have any problems with dirt in the valves. The lifetime of the hydraulic pump and motor will undoubtedly be extended now that we are using the CJC® fine filter. The results from the oil analyses are excellent.”

“The hydraulic servo valves are no longer failing due to contaminants in the oil. We have made huge savings on the components and labour along with mill downtime relating to the servo valves on the bandsaw log carriage.”

„Since the installation of the CJC® Offline Filter we have never had to clean or to do maintenance on the valves.“

„After knowing CJC® Filters and having installed them on our injection machines, we have got the suitable oil quality and reduction of yearly unplanned stoppages from 18 to 2 times. At present we are certain to work with oil in very good conditions and suitable at all times for our facilities. The investment to install CJC® Filters was a right decision and a pro-assets good maintenance tool.“

“Because we are satisfied with the performance of CJC® Off-line Filtration, we are considering the purchase of additional CJC® Off-line Oil Filtration units.”