Avoid oil changes, repair costs and “off-hire” times

Thruster filters from CJC®: Your solution for consistently dry and clean oil

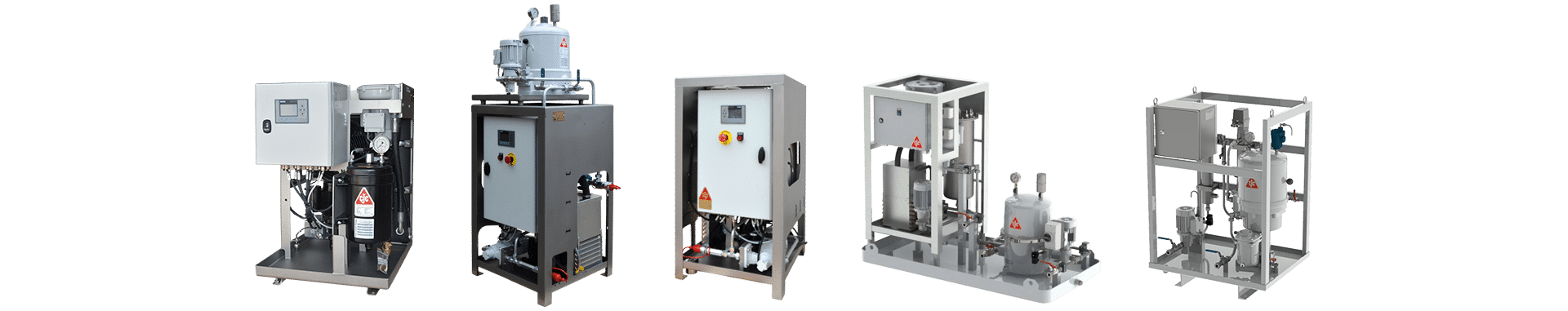

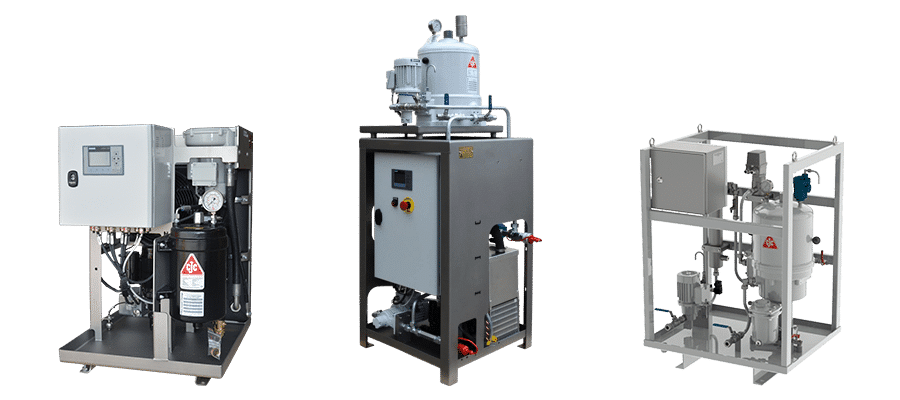

Thruster Filters

Thruster Filters from CJC® dry, clean and maintain your gear oil quickly and cost-effectively. Whether fixed propeller or variable pitch propeller, whether fishing boat or container ship, whether mineral oil or biodegradable lubricant, CJC® Thruster Filters are precisely configurable for your ship. Installed in the offline or lube oil circuit, they continuously ensure maximum oil cleanliness. They remove water, wear particles, oil degradation products and acids — even microbial infestation — efficiently and reliably.

How you benefit from installing a CJC® Thruster Filter

Product Advantages — CJC® Thruster Filters

Flexible all-rounder

CJC® Thruster-Filter dry each gear oil independent from additives, viscosity and air content in the oil. Optionally with oil sensors for integration into your condition monitoring system.

Maximum oil cleanliness

Clean and dry gear oil within a very short time. The CJC® Thruster Filter removes all contaminants – independently, continuously and highly efficiently. For maximum service life of oil filling and thruster components.

Economical & ecological

Depth filter made of 100% natural fibers — 0% plastic and 0% metals. High recording capacities and thus long filter life ensure excellent price-filter performance of the CJC® Thruster Filters.

Easy installation & maintenance

Easy and flexibel installable in an independent circuit — e. g. as offline filter. Filter change is possible during thruster operation. Low-maintenance, robust and durable, the CJC® Thruster Filter also convinces.

Details about your products — CJC® Thruster Filter

The various concepts for the dewatering, filtration and care of gear oil, as well as the modular design, make it possible to adapt our thruster filters individually to your stern or bow thruster. They are ideal for counteracting the continuous ingress of water into thrusters and keeping the gear oil consistently dry and clean — free of water, particles and oxidation residues. For decades, we have documented the oil cleanliness achieved on various thruster drives and vessel types. Achieve a longer service life for your thruster drives quickly, efficiently and cost-effectively and avoid unnecessary failures and off-hire times for a more economical operation.

Modular design and individually configurable:

Oil volume, max.: 800 Litres

Installation: flexible, e.g. in the offline or lubricating oil system

Design temperature: 80 °C

Viscosity range: ISO VG 32—150

Water content in the oil, max.: 700,000 ppm (70%)

Water separation: water content permanently < 100 ppm (0.01%)

Dirt holding capacity: up to 2 kg

Filtration degree: 3 μm absolute, 1 μm retention rate

Supply voltage: 1 x 208 V/60 Hz, 1 x 230 V/50—60 Hz, 3 x 380—420 V/50 Hz or 3 x 440—480 V/60 Hz

Power consumption: 1.85 kW

Current: 8.4 A at 208 V and 230 V or 3.3 A at 380—480 V

Pump flow (24/7): 30—36 litres per hour

Design pressure: 6.5 bar

Weight, approx.: 108 kg

Dimensions, L x B x H: 515 x 517 x 786 mm

Equipment:

Standard:

- Pump with motor

- integrated CJC® Depth Filter Insert

- lectrical control with integrated alarm system (e.g. pressure and leakage sensor)

- Leakage monitoring

- Sampling point

- Automatic water separation

- START/STOP switch – dewatering process

Optional:

- Shock absorber

Oil volume, max.: 3,000 Litres

Installation: flexible, e.g. in the offline or lubricating oil system

Design temperature: 60 °C

Viscosity range: ISO VG 32—320

Water content in the oil, max.: 700,000 ppm (70%)

Water separation: water content permanently < 100 ppm (0.01%)

Dirt holding capacity: up to 12 kg

Filtration degree: 3 μm absolute, 1 μm retention rate

Supply voltage: 1 x 208 V/60Hz, 1 x 230 V/50—60 Hz, 3 x 400/50Hz or 3 x 440—480 V/60 Hz

Power consumption: 2.7 kW at 208 V, 2.9 kW at 230 V or 3.2 kW at 400 V and 440—480 V

Current: 15.5 A at 208 V, 12.5 A at 230 V or 5.1 A at 400 V and 440—480 V

Pump flow (24/7): 45—55 Litres per hour

System pressure (oil inlet), max.: 0.5 (PV) or 3.5 bar (PVM)

Weight, approx.: 170 kg

Dimensions, L x B x H: 570 x 570 x 1,635 mm

Equipment:

Standard:

- Pump with motor

- integrated CJC® Depth Filter Insert

- electrical control with an integrated alarm system

- Leakage monitoring

- Sampling point

- automatic water separation

Oil volume, max.: 3,000 Litres

Installation: flexible, e.g. in the offline or lubricating oil system

Design temperature: 60 °C

Viscosity range: ISO VG 32—320

Water content in the oil, max.: 700,000 ppm (70%)

Water separation: water content permanently < 100 ppm (0.01%)

Supply voltage: 1 x 208 V/60Hz, 1 x 230 V/50-60 Hz, 3 x 400/50Hz or 3 x 440—480 V/60 Hz

Supply voltage: 2.6 kW at 208 V and 230 V, 3 A at 400 V and 440—480 V

Current: 12.5 A at 208 V, 11.3 A at 230 V, 4.3 kW at 400 V and 3.9 kW at 440-480 V

Pump flow (24/7): 45—55 Litres per hour

System pressure (oil inlet), max.: 0.5 (PV) or 3.5 bar (PVM)

Weight, approx.: 125 kg

Dimensions, L x B x H: 570 x 570 x 1,000 mm

Equipment:

Standard:

- Pump with motor

- electrical control with integrated alarm system

- Leakage sensor

- Sampling point

- automatic water separation

- Coolant cooling

Oil volume, max: 1,000 Litres

Installation: flexible, e.g. in the offline or lubricating oil system

Design temperature: 60 °C

Viscosity range: up to ISO VG 220

Dirt holding capacity: up to 12 kg

Filtration degree: 3 μm absolute, 1 μm retention rate

Motor voltage: Direct or alternating current

Power consumption: 0.18 kW

Capacity: 90—300 litres per hour

System pressure (oil inlet), max.: 0.5—10 bar

Operation pressure, max. : 2 bar

Design pressure, max. : 7 bar

Equipment:

Standard:

- Pump with motor

- integrated CJC® Depth Filter Insert

- Preheater

- Sampling point

- automatic water separation

Optional:

- electrical control — independent placement possible for flexible integration into your engine compartment

- Pressure switch

- Leakage sensor

The integrated depth filters for gear oil care

Separation capacity:

- Water – free, emulsified and dissolved

- Wear particles, salt crystals (seawater) and other suspended solids

- Oxidation residues (varnish, sludge)

- Acids

Type of filtration:

- Depth filter with extremely high recording capacity

Inner surface:

- 120—150 m² per gram

- The largest depth filter insert has an internal surface of > 2,066 ha = > 2,894 football fields

- The smallest depth filter insert has an inner surface of > 5 ha = > 7 football fields

Due to the modular design, the number of various depth filter inserts and thus the holding capacity can be adapted to the individual dirt input.

Volume:

- The largest depth filter insert has a volume of > 504 Litres

- The smallest depth filter insert has a volume of > 1.5 Litres

Filtration degree:

- 3 µm absolute, retention rate down to 1 µm (Micrometer)

Filter material:

- 100% natural fibres – meets the requirements of the Circular Economy Act

Customer cases

Find out in our application studies how operators benefit from the installation of the CJC® thruster filters.

“Only with the CJC® Thruster Filter could the transmission oil finally be dried satisfactorily. Without CJC®, we would have had to change the 1,500 litres of transmission oil soon. By avoiding the oil change, we were able to save 4,890 EUR (3.26 EUR/litre) – an important contribution not only in terms of budget, but also in terms of resource conservation. The excellent results convinced us, so that we decided to purchase two identical CJC® systems for our tugs “Bugsier-5” and “Bugsier-6”.

“The CJC® Thruster Filter allows us to remain the tug in operation for 6 months before its next technical shutdown. The results of the oil analyses are clear and clearly demonstrate the effectiveness of the CJC® Thruster Filter.”

„After having tested nearly every piece of water removing equipment on the market in order to solve our water and contamination problem, we went for the CJC® Thruster Filters, because it was simply the best. The filters did the job to our greatest satisfaction, removing particles, water and other waste products. CJC® Thruster Filters for oil maintenance are a very good investment. The return of investment is very short.“

Contact your maritime technical salesperson now

Let’s talk about your thruster, your gear oil and the specific challenges. We filter every gear oil. It does not matter whether you use mineral oil or biodegradable lubricant. Together with you, we maximize the service life of oil filling and thruster.

Receive a personal consultation and a non-binding offer about a CJC® thruster filter for the efficient care and filtration of gear oil.

Write or call me.