Fine Filter Unit 727/108 for quenching oil

The CJC Fine Filter Unit 727/108 for quenching oil is an exclusively developed product variant for fine filtration and fluid care of quenching oil. Contaminants, which load the quenching oil and therefore have negative consequences for the hardening process as well as for the whole oil system, are removed from the oil with high efficiency:

- Particles (soot, cinder, metal and dust particles, cover pastes etc.)

- Water (condensation, leakages in the cooling system etc.)

- Cracking products (asphaltenes, sludge etc.)

- Oxidation residues (only in the case of open quench baths)

Please, contact us when using aqueous quenching fluids!

ADVANTAGES

- Produce quenching results with consistent quality – stabilized cooling curve and cooling time due to improved oil cleanliness

- Reduce black deposits and sludge formation on hardened parts, coolers, circulating systems and in tanks

- Avoid after-treatment and additional cleaning processes

- Protect washing baths – residue-free hardened parts minimize ingress of contamination

- Continuous filtration independent from cooling circuit and operation of the quenching system (24/7)

- Filter material made of 100 % renewable raw materials protects the environment and allows easy disposal

FUNCTION PRINCIPLE

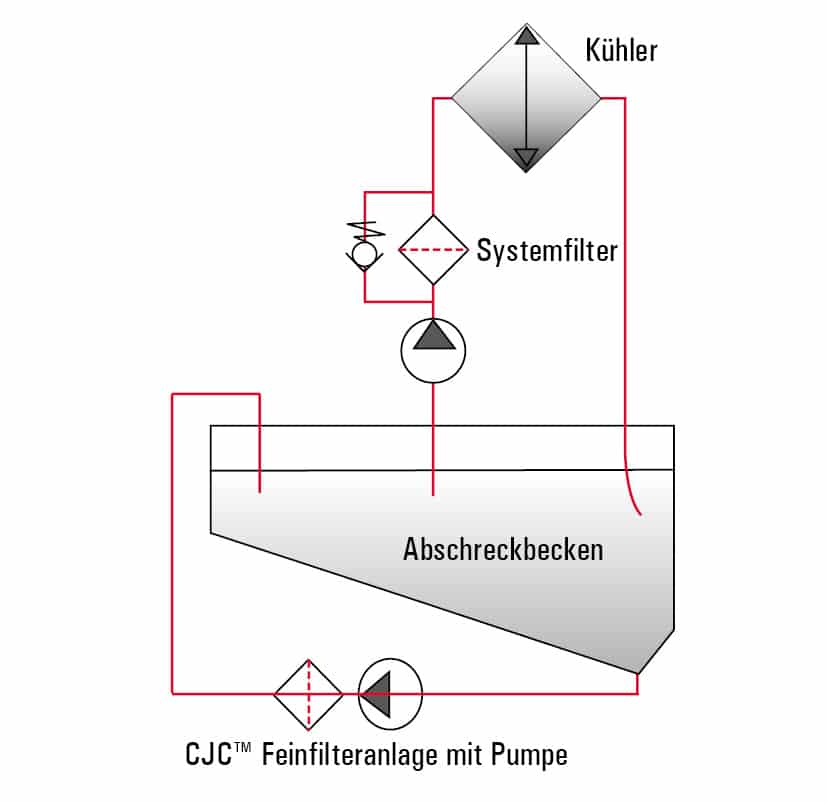

The off-line filtration enables due to the separate, independent circuit an optimum adjustment of the pump flow to operating fluid and fine filtration to a range of 3 µm absolute respectively down to 1 µm nominal.

The CJC Fine Filter Unit draws the contaminated oil from the quenching system. Slowly and with constant flow rate the oil passes the CJC depth filter insert radially from the outside to the inside. Due to the slow pace of the oil flow and the extremely long filter paths, CJC depth filter inserts are particularly effective. The longer the fluid has contact with the filter material, the more effective is the fine filtration and fluid care.

| Technical data | ||||

|---|---|---|---|---|

| CJC Fine Filter Unit | 727/108 | |||

| Oil volume, max. | 15,000 l | |||

| Material filter housing | Steel | |||

| Pump flow | 1,440 l/h | |||

| Power consumption, approx. | 0.55 kW | |||

| Pressure drop, max. | 2 bar | |||

| Filter insert, type |

JH 727/108 | |||

| Filter material | 100 % renewable raw materials (cellulose) | |||

| Filtration degree |

3 down to 1 micron | |||

| Cavities |

> 252 l |

|||

| Dirt holding capacity |

> 56 kg in the case of quenching oil up to 280 kg – depends on the type of contamination |

|||

| Water holding capacity |

> 28 l | |||

| Equipment | ||||

| Standard |

|

|||

NOTE

The filter size 727/108 is designed for closed quenching baths with a max. oil volume of 15,000 litres and for open quenching baths with a max. oil volume of 10,000 litres. Dimensioning differs for larger oil volumes or open quenching baths – please, contact us!