Operate your machines only with clean and dry lubricant

Desorber-Filter-Unit D5 from CJC®: Your solution for fine filtration and drying of oils

Desorber-Filter-Unit D5

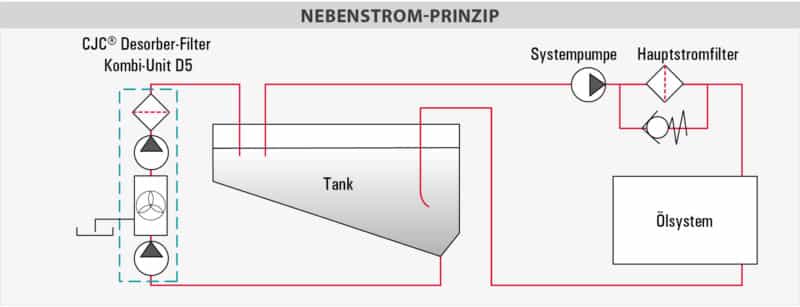

CJC® Desorber Filter Units D5 dry your oils and fluids within a very short time and reduce the water content to < 0.01%. They remove free, emulsified and dissolved water from the oil. The integrated depth filter retains particles and oil degradation products (acids, varnish, sludge). Ideal for hydraulic and lubrication systems as well as gearboxes, whether operating with mineral oil or synthetic fluid. Even oils with a water content of up to 70% and poor water separation capacity can be dried and treated. Thanks to the installation in a separate circuit in the bypass flow or on a free-standing tank, the Desorber-Filter-Unit D5 maintains your oil continuously and independently of the operation of the machine. The drying of oils is based on the principle of desorption — the water separation efficiency is independent of viscosity and air content in the oil and has no influence on additives.

How you benefit from the installation of a CJC® Desorber Filter Unit D5 on your machine

Keeping oils and fluids as clean and dry as possible is the be-all and end-all for reliably functioning machines and smooth processes.

Application areas & installation example — Desorber-Filter-Unit D5

Especially in the paper, steel, plastics and metal processing industries, as well as in maritime applications, there is a high risk of water entry into the oil systems due to environmental and process conditions.

Desorber:

The pump in the oil inlet sucks in the oil. In the desorber chamber, the warm, moist oil meets a counterflow of cold, dry air. The oil heats the cold air, which allows it to absorb a lot of moisture (system pressure constantly low < 2 bar). In a subsequent process, the warm, moist air cools down, and the water condenses again.

Fine filter system:

After the desorption process, the fluid flow passes through the filter with the integrated fine and depth filter insert. Water but also particles in the oil accelerate the degradation of base oil and additives. The filter removes both particles and already formed reaction products (acids, sludge, varnish).

Features — Desorber-Filter-Unit D5

Oil volumen, dimensioning e.g.: 800 Litres

Installation: flexible, e.g. in the off-line circuit or on a free-standing tank

Design temperature: 80 °C

Viscosity range: up to ISO VG 150

Water content in the oil, max.: 700,000 ppm (70%)

Water separation: water content permanently < 100 ppm (0.01 %)

Dirt holding capacity: up to 2 kg

Filtration degree, max.: 3 μm absolute to 1 μm

Fine and depth filter insert: 1 piece

Supply voltage: 1 x 208 V/60Hz, 1 x 230 V/50—60 Hz, 3 x 380—420/50Hz or 3 x 440—480 V/60 Hz

Power consumption: 1.85 kW

Current: 8.4 A at 208 V and 230 V or 3.3 A at 380-420 V and 440-480 V

Pump flow (24/7): 30—36 litres per hour

Design pressure, max.: 6.5 bar

Weight, approx.: 108 kg

Dimensions, L x B x H: 515 x 517 x 786 mm

Equipment:

Standard:

- Pump with motor

- electrical control with integrated alarm reporting system (e.g. pressure and leakage sensors)

- Leakage monitoring

- Sample point for oil and fluid analysis

- automatic water separation

- START/STOP switch — dewatering system

Download product data sheet:

All sizes and variants — without and with fine filter

That say our customers

“I am completely satisfied with the investment. Oil drying takes place very quickly and without machine downtime. Thus, we keep the production stable, have time to look for the failure cause, avoid the oil change and waste oil disposal, and maintain the oil quality.”

“The Desorber works excellently in this application. I was impressed by the results and surprised how efficiently the Desorber dewatered the oil. The Desorber is easy to operate and is low-maintenance.”

“The CJC® Desorber allows us to operate the tug boat until the regular inspection in the dry dock in 6 months. The oil analysis results speak for themselves and substantiate the efficiency of the Desorber.”

“It was only with the Desorber that the gear oil could finally be dried satisfactorily. Without CJC®, we would have had to change the 1,500 litres of gear oil soon. By avoiding the oil change, we were able to save EUR 4,890 (EUR 3.26/litre) – an important contribution not only in terms of budget but also in terms of resource savings. The excellent results convinced us, so we decided to purchase two identical Desorbers for our tug boats, “Bugsier 5” and “Bugsier 6”.

“The Desorber is ideal for such operations because it works continuously while the vessel is at sea. The results are very satisfactory. The Desorber works very well and will further reduce the water content.”

Write or call your regional contact person now

Let us start a conversation about your system, your oil, and the specific challenges. We are your experts for oil drying whether with acute or permanent water ingress — and even with highly viscous oils and stable emulsions.

Receive a personal consultation and a non-binding offer for a CJC® Desorber Filter Unit D5.

Write or call us.