Filter Separator 727/- Diesel

The CJC Filter Separator 727/- removes large amounts of water as well as particles, oil degradation products (oxidation products, sludge), microorganisms and acid compounds from diesel due to the unique combination of filter material and filtration type with extremely high efficiency. Specially optimised for diesel, it is used on diesel engines as well as storage/bunker tanks. Specially optimised for diesel, it is used on diesel engines as well as storage/bunker tanks.

Water in diesel promotes the formation of microorganisms (bacteria, fungi, yeasts). The generated bio-sludge clock system filters and fuel lines and thus can lead to malfunctions within engines. By an increasing number of microorganisms, the risk of corrosion damages in tank and fuel system rises. For diesel-operated means of transport and emergency power generators with long periods of non-operation, the risk is exceptionally high.

CJC Fine Filter Inserts are the only filters in the world-wide that, combines with an exceptionally high dirt holding capacity, simultaneously minimize all four types of contamination and consist of 100 % renewable raw materials.

TYPICAL APPLICATIONS

- Diesel engines

- Storage tanks

- Bulk tanks/bulk carrier

ADVANTAGES CJC FILTER SEPARATOR 727/- DIESEL

- longer lifetime for engines, injection nozzles, pistons, cylinders and fuel pumps

- less cost-intensive engine failures

- improved engine performance

- simultaneous removal of water, particles, oil degradation products and acid compounds – as well as microorganisms (bacteria, fungi, yeasts)

- high filter efficiency due to continuous fine and depth filtration combined with coalescing filtration, independent from the operation of the engine

- constantly high fuel cleanliness

- Protection against sludge accumulation and the resulting malfunctions

- reduce extensive tank cleaning

FUNCTION PRINCIPLE

The CJC Fine Filter Insert specially developed for diesel, is a depth filter which offers a long contact time between filter material and diesel, providing an exceptionally high filter efficiency and dirt holding capacity. Contaminants are permanently retained in the depth of the filter material. Simultaneously, the filter material coalesces finest water droplets, which are separated from the diesel in a subsequent process.

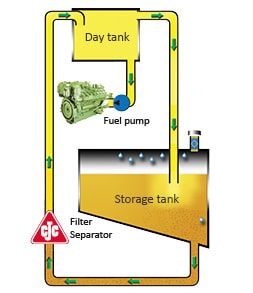

INSTALLATION EXAMPLE

Ideally, the suction pipe of the CJC Filter Separator is connected to the drain valve at the bottom of the storage tank, meaning that also sediments are filtered out. The cleaned diesel returns to the day tank – or via overflow pipe into the storage tank.

| Technical data | |||||

|---|---|---|---|---|---|

| CJC Filter Separator for Diesel | 727/54 | 727/81 | 727/108 | 727/162 | |

| Pump flow, max. | 5,250 l/h | 7,875 l/h | 10,500 l/h | 11,900 l/h | |

| Material filter housing | Steel or stainless steel | ||||

| Power consumption, mind. | 1.1 kW | ||||

| Design pressure | 2 bar | ||||

| Filter inserts | 14 pieces | 21 pieces | 28 pieces | 42 pieces | |

| Filter capacity— CJC Fine Filter Insert 727/- | |||||

| Filtration degree | 3 down to 1 micron | ||||

| Dirt holding capacity, approx. | 28 kg | 42 kg | 56 kg | 84 kg | |

| Water separation | automatic | ||||

| Equipment / Certification | |||||

| Standard |

|

||||

| Optional |

|

||||

| Certification on request, e. g. |

|

||||