Lubricant Care Dual-Fuel Engine | Passenger vessel, car ferry

Customer Case

System — Dual-Fuel Engine

Vessel: Passenger Vessel, ferry M/F “PRINSESSE ISABELLA”

Main engine: 4-stroke dual-fuel engine, type Wärtsilä 6L20DF

Lubricant: Texaco HDAX 5200

Oil volume: 375 Litres

Fuel: MGO, LNG, dual-fuel

Passenger vessel, ferry M/F “PRINSESSE ISABELLA”

Challenge

M/F „PRINSESSE ISABELLA“ was experiencing dirty and black lube oil for the main engines. Whenever the oil volume was replaced with new oil, its colour changed from almost golden to black in 8 hours. The lubricating oil was previously only treated using automatic main inline filters. Only when the water content in the oil increased was the centrifuge used or the oil changed. Operation and maintenance of the centrifuge were time-consuming, cost-intensive and impractical – the design shortcoming: the sludge tank of only 1 m³. When the centrifuge was in operation, the sludge tank had to be emptied frequently and the oil-water mixture disposed of. The chief engineer did not have the time to maintain the centrifugal separator, as the task required a full working day, and only one person was on board the vessel responsible for the engine room. The chief engineer wanted to install an oil filter to minimize the wear on the engine components caused by the particles and impurities in the lubricating oil.

Environmental Benefit

Furthermore, Samsø Rederi is managed by the commune of Samsø, which is currently 100% CO2 neutral. For this reason, the management of the M/F PRINSESSE ISABELLA also focuses on minimizing the environmental impact. The ship is already designed to keep pollution to a minimum. In addition, optimization options are constantly being sought. The aim was to extend the service life of the lubricating oil in order to further reduce environmental influences and lower operating costs.

Solution — CJC® Lube Oil Filter

The centrifugal separator was replaced with a CJC® Marine Lube Oil Filter 27/81. The integrated CJC® Depth Filter Insert consisting of 100 % natural fibres, removes particles, water, oil degradation products and acids from the oil.

Dirt holding capacity: approx. 6 kg

Wasseraufnahmekapazität: > 2,7 Liter

Filtration degree: 3 µm absolute, retention rate < 1 µm

Test

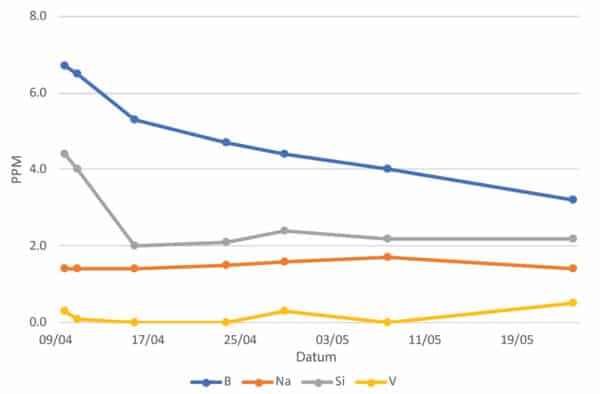

For a test period of two months an independent oil laboratory analyzed the oil samples, which were taken in an interval of one sample every 1-2 weeks. The oil samples were taken in the upstream flow

of the CJC® Lube Oil Filter at the integrated sample point of.

The happy crew of the car ferry with the CJC® Lube Oil Filter, which replaces a lube oil separator.

CJC® Lube Oil Filter installed on the main engine, dual-fuel engine Wärtsilä 6L20DF, fuel: MGO/LNG, dual-fuel

Result of Lubricant Care

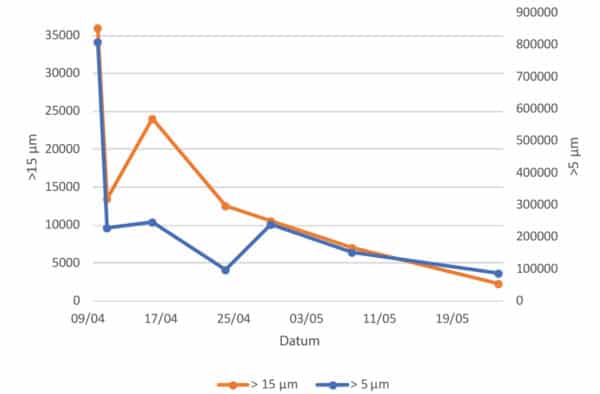

The CJC® Lube Oil Filter led to better oil quality overall. In just 6 days, the cleanliness class improved from ISO 20/16 to 18/15 and in 1.5 months to 17/12 (ISO 4406). Furthermore, it was recorded that the general trend for contaminants and wear elements present in the oil was starting to decrease.

Savings & Benefits for our customer:

Installing the CJC® Lube Oil Filter on the oil sump of the main engine (dual-fuel engine, 4-stroke) resulted in the below benefits for our customer:

- decreased environmental impact

- less sludge production (compared to centrifuge)

- decreased lube oil consumption due to longer refill and oil change intervals

- expected component lifetime extension by a factor of 3–5 (source: Noria Corp.)

Particle content in 100 ml lubricant

| BEFORE | after 6 days with CJC® Marine Lube Oil Filter |

after 1,5 months with CJC® Marine Lube Oil Filter |

|

| Particles > 5 µm |

808.480 | 246.530 | 87.840 |

| Particles > 15 µm |

36.010 | 24.020 | 2.330 |

| ISO Code 4407 *) | 20/16 | 18/15 | 17/12 |

*) Laboratory report from Filtrex Services.

Customer Comment

“The difference between the oil condition before and after installing the CJC® Lube Oil Filter is clearly visible — the color of the oil is a bit more golden again. The biggest challenge with the centrifuge is that it discharges a lot of oil sludge. Although the sludge consists of 90-95% water, the disposal of this oil-water emulsion, as well as the entire operation of the centrifuge, is very costly.”

Christian Damhøj Jensen, Chief Engineer

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Get detailed information on oil analyses, savings and calculations as well as a personal consultation specifically for your dual-fuel engine, your engine lubricating oil and your passenger ship.

Write or call me.