Lube Oil Filtration, Main Engine, Diesel Electric Propulsion | Ferry

Customer Case

Challenge

On the M/F Tycho Brahe, the lubricating oil (diesel-electric drive) was still cleaned conventionally using a centrifuge for two engines. The cost of operation for each of the centrifuges amounted to EUR 13,000 — in total, 26,000 EUR per year. The principal costs occur for the energy consumption of the heating.

Solution: CJC® Lube Oil Filter

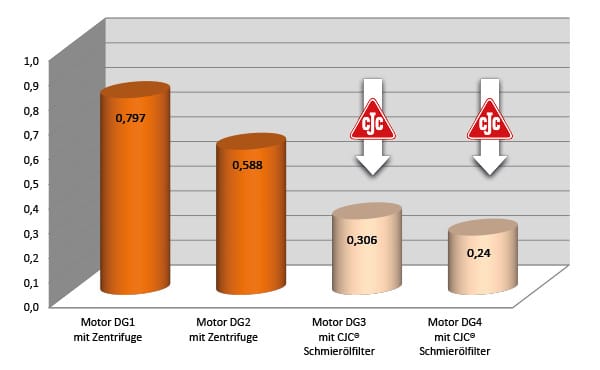

A CJC® Lube Oil Filter 27/108 was installed on both the DG3 and DG4 main engines – a standard version (DG3) and the newly developed marine version with frequency regulator and higher flow rate (DG4). The centrifuge was left running on the main engines DG1 and DG2 for reference.

Main engine Wärtsilä 6R32

CJC® Lube Oil Filter 27/108

Advantages of lube oil care

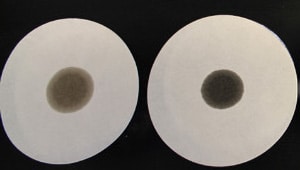

The target was to deliver results equal to or better than the centrifuge. The objective was achieved from both CJC® Lube Oil Filters (the standard and the prototype version). For the crew, the result was impressive The crew reported visual oil appearance as “new oil” and a significant difference compared to the oil on DG1 and DG2 (with centrifuge). The direct benefit of installing the CJC® Lube Oil Filters was energy savings regarding the heating. Also, a substantial drop in lube oil consumption on the main engines DG3 and DG4 (with CJC® Lube Oil Filters) compared to the consumption on DG1 and DG2 (with centrifuge). The test was a success considering the savings and the gained results for more than 12 months.

Advantages compared to centrifuges

- Lower energy consumption (no heating) and lower maintenance costs

- Savings: EUR 13,000 per year – EUR 26,000 once the second centrifuge has also been replaced by a CJC® oil maintenance system

- Significantly less lubricating oil loss and therefore less fresh oil required

- Savings: EUR 3,356 to 4,027 per year

- Less diesel consumption and fewer emissions

- Easier sludge handling (no sludge tank)

- Drastically reduced amount of produced oil sludge

- Savings: EUR 2,013 per year

- Short amortization period

- Lubricating oil filter in the standard version: less than 7 months

- Lubricating oil filter in the newly developed marine version: just over 12 months

Environmental benefits

Reducing energy consumption for heating the oil leads to a decrease in diesel consumption and thus lower emissions. Equally, the amount of sludge has been significantly reduced, so less new lube oil to replenish the sump is needed.

Oil Sample – Centrifuge

Main engine DG1 and DG2

Oil samples – CJC® Lube Oil Filter

Main engine DG3 and DG4

Diesel consumption per hour [Liter]

Centrifuge vs CJC® Lube Oil Filter

Customer Comment

“We have had nothing but positive experiences with CJC® Oil Filters. The quality of the oil is as good as before, even better in every respect. The oil color has changed from dark to light and corresponds to that of new oil.

We save the man-hours and chemicals that would have been needed to clean the centrifuge, and the machine room has become clearer.

Also, no sludge is produced during filtration – the centrifuge, on the other hand, feeds out every hour. Displacement water is used for cleaning. The oil loss that occurs during centrifugation contaminates the water. The resulting sludge is made up of approx. 0.2 liters of oil and approx. 2.5 liters of water and is fed directly into the sludge tank. With 8,700 discharges annually, this corresponds to 1,740 litres of oil and 21,750 litres of water. The costs to dispose of the sludge amounted annually approx. EUR 2,013.We also save on lubricating oil. This is because the oil loss that occurs during centrifuging and when the centrifuge malfunctions amounts to approx. 2,500 to 3,000 liters per year. At the cost of approx. 1.34 EUR per litre, we save 3,356 – 4,027 EUR each year.

A good investment all round and if we don’t switch to electric drive, we will definitely install oil filters on the DG1 and DG2 engines too.”

Senior C/E, Scandlines, Henrik Fald Hansen

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Receive detailed information on the oil analyses, savings and calculations and a personal consultation specifically on your main engine, your lube oil and your requirements and goals.

Write or call me.