Maximize the service life of your cooling lubricants and tools

Cooling lubricant filters from CJC®: Your solution for the highest coolant purity within a very short time

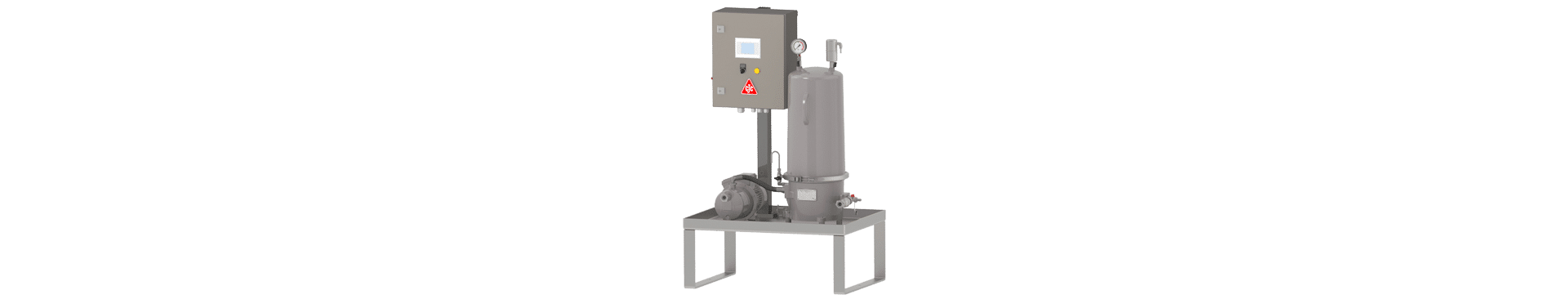

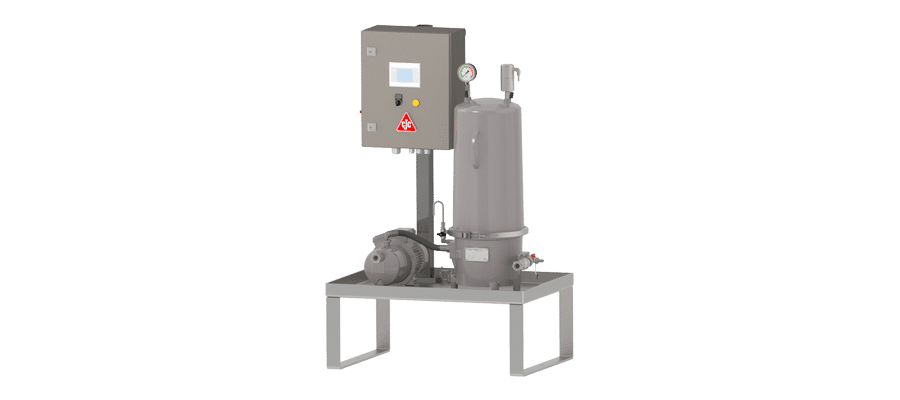

Cooling lubricant filter

Cooling lubricant filters from CJC® clean and maintain your cooling lubricant quickly and cost-effectively. Whether machining centres or individual machine tools, whether central supply or small tank, whether aqueous or non-aqueous cooling lubricant, CJC® cooling lubricant filters are precisely configurable for your application. Installed in the offline circuit or on the IBC tank, they ensure maximum cooling lubricant cleanliness regardless of the process. They remove metallic chips, fine rod abrasion, sticky deposits, metal salts, foreign oils, greases and/or water — even microbial infestation — efficiently and reliably.

How you benefit from installing a CJC® cooling lubricant filter

Product Advantages — CJC® Cooling Lubricant Filter

Customized solutions

Perfectly adaptable to any tank size and cooling lubricant. The CJC® Cooling Lubricant Filter is individually and optimally configurable, thanks to its modular design. Optionally with customer-specific sensors for integration into your condition monitoring system.

Maximum coolant purity

Highest cooling lubricant cleanliness and clean fluid system within a very short time. The CJC® Cooling Lubricant Filter removes all impurities – process-independent, continuous and highly efficient. For maximum service life of cooling lubricant and tools.

Economical & ecological

Depth filter made of 100% natural fibres – 0% plastic and 0% metals. High absorption capacities and thus long filter life ensure excellent price-performance ratio of the CJC® Cooling Lubricant Filters.

Easy installation & maintenance

Easy to install in an independent circuit — as an offline filter or for recovery on the IBC tank. This also means filter changes without production downtimes. Low-maintenance, robust and durable, the CJC® Cooling Lubricant Filter also convinces.

Write or call your regional contact person now

Do you have any questions about our cooling lubricant filters, rental-purchase options or cleaning and maintaining cooling lubricants? Is your cooling lubricant exceptionally heavily loaded and you do not know whether it can be cleaned cost-effectively? Our regional contacts will be happy to help you find out exactly that. Just call or e-mail.