Minimize the water content in the oil — even with stable emulsions

Desorbers from CJC®: Your solution for fast and reliable oil dewatering

Desorber for oil dewatering

CJC® Desorbers are a fast, reliable and cost-effective solution for dewatering oil from lubricants. Whether hydraulics, gearboxes or lubricating oil systems — our technology effectively removes water from both mineral oils and synthetic fluids, regardless of viscosity, additives or air content.

The water content is permanently reduced far below the saturation limit of the lubricant — as both emulsified and dissolved water is permanently separated. Even stable water oil emulsions can be efficiently dried.

Installed in the offline circuit or on a free-standing tank, CJC® Desorbers work independently of machine operation and thus ensure continuous, process-decoupled oil dewatering. In combination with an optional fine filter system, solid particles, oil ageing products and acids are also removed — for maximum oil cleanliness and an extended service life of the lubricants and machine components.

How you benefit from installing a CJC® Desorber:

- Protects againgst corrosion, cavitation and premature oil ageing.

- Comprehensive wear protection in combination with a CJC® Fine Filter

- Increased operational reliability and system availability

- Extended lifetime of components and lubricants

- Improved return on investment due to significantly lower operating costs

- More sustainable plant operation: reduced resource consumption andCO2 footprint

Flexible all-rounder

CJC® Desorber dry each lubricant — independent of viscosity and additives. Optional with fine filter and condition monitoring.

High drying efficiency

Fast, reliable and process-independent oil dewatering – for absolutely dry oil and maximum operational safety.

Easy installation & maintenance

Easy to install, low-maintenance in operation and immediately ready for use. Mostly amortized within the first year.

Economical & ecological

CJC® Desorber arbeiten energieeffizient, reduzieren den Ersatzteil- und Ölverbrauch und senken Ihre Betriebskosten.

After solids, water is the second most common cause of failures and malfunctions in lubricating oil and hydraulic systems. Your solution: CJC® Desorber

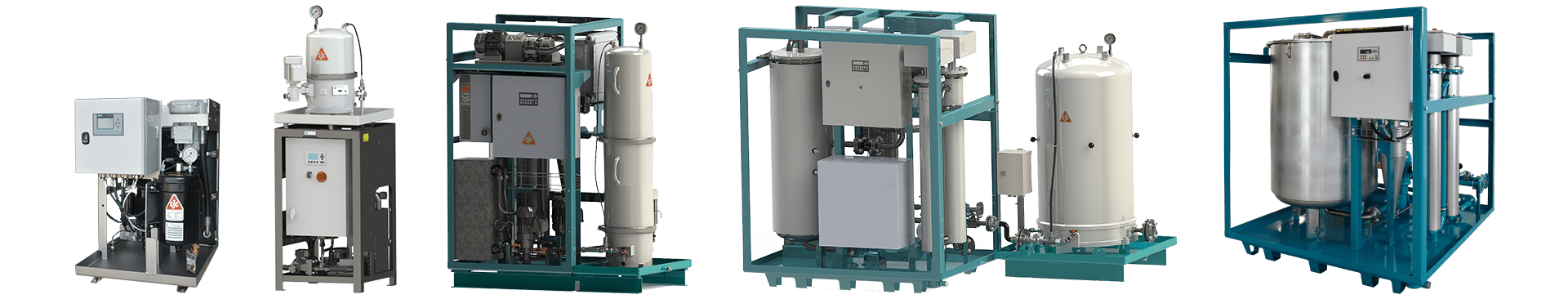

Sizes & variants — CJC® Desorber for oil dewatering

Combined with CJC® Depth Filter for additional cleaning and fluid care

Speak with your regional expert about Desorber for oil dewatering

Whether acute or permanent water ingress—we will find the right solution for oil drainage. Our fluid experts are on hand to help you even with difficult requirements – always with the aim of providing you with sustainable and profitable concepts.

- Personal advice – by telephone or directly on site at your application

- Assessment of your oil analyses – with solution-oriented recommendations

- Support even for special and complex challenges

That say our customers

“I am completely satisfied with the investment. Oil drying takes place very quickly and without machine downtime. Thus, we keep the production stable, have time to look for the failure cause, avoid the oil change and waste oil disposal, and maintain the oil quality.”

“The Desorber works excellently in this application. I was impressed by the results and surprised how efficiently the Desorber dewatered the oil. The Desorber is easy to operate and is low-maintenance.”

“The CJC® Desorber allows us to operate the tug boat until the regular inspection in the dry dock in 6 months. The oil analysis results speak for themselves and substantiate the efficiency of the Desorber.”

“It was only with the Desorber that the gear oil could finally be dried satisfactorily. Without CJC®, we would have had to change the 1,500 litres of gear oil soon. By avoiding the oil change, we were able to save EUR 4,890 (EUR 3.26/litre) – an important contribution not only in terms of budget but also in terms of resource savings. The excellent results convinced us, so we decided to purchase two identical Desorbers for our tug boats, “Bugsier 5” and “Bugsier 6”.

“The Desorber is ideal for such operations because it works continuously while the vessel is at sea. The results are very satisfactory. The Desorber works very well and will further reduce the water content.”